Mejore la resistencia de unión de los materiales curables con luz con información sobre el nivel de dinas

En el ámbito de la ciencia y la ingeniería de los materiales, en particular en los campos que aprovechan los adhesivos para aplicaciones de ensamblaje o recubrimiento , el concepto de nivel de dinas desempeña un papel fundamental. El nivel de dinas, que a menudo se expresa en dinas/cm (dyn/cm), es una medida de la energía superficial, y los valores más altos indican la humectabilidad de un material. Cuanto mayor sea la energía superficial o mayor sea el nivel de dinas de la superficie, más posibilidades tiene un adhesivo de adherirse a ella. Esta métrica es particularmente significativa en la fabricación de plásticos y para los ingenieros de diseño encargados de garantizar la eficacia y la durabilidad de las uniones de los sustratos, especialmente cuando se utilizan adhesivos UV.

adhesivos UV Tienen propiedades de curado rápido y formidables resistencias de unión. No obstante, el rendimiento de estos adhesivos está intrínsecamente vinculado al nivel de dinas de los sustratos a los que se aplican. Idealmente, un sustrato debe poseer un nivel de dinas superior a la tensión superficial del adhesivo para facilitar una humectación y adhesión óptimas. Esto se basa en el principio de que el adhesivo puede "humectar" eficazmente la superficie, si tiene la mejor oportunidad de formar una unión sólida y homogénea. Por el contrario, un sustrato con un nivel de dinas inferior a la tensión superficial del adhesivo puede provocar una humectación subóptima, lo que produce uniones más débiles y posibles fallas del producto. Las químicas de los adhesivos Dymax (acrilatos modificados con poliuretano) tienen alrededor de 30-47 dinas.

Los requisitos para sustratos Por lo tanto, están íntimamente relacionados con sus niveles de dinas. Diversos materiales, como plásticos, metales y vidrio, presentan características de energía superficial distintivas que se pueden alterar o tratar para lograr un nivel de dinas específico. Las técnicas como los tratamientos con corona, llama o plasma pueden aumentar el nivel de dinas de los sustratos plásticos, haciéndolos más susceptibles a la adhesión.

Para cuantificar el nivel de dinas de un sustrato se aplican fluidos de prueba con tensiones superficiales conocidas. Al observar la interacción de estos fluidos con el sustrato (ya sea que formen perlas o se esparzan), se puede obtener una aproximación de la energía superficial del material.

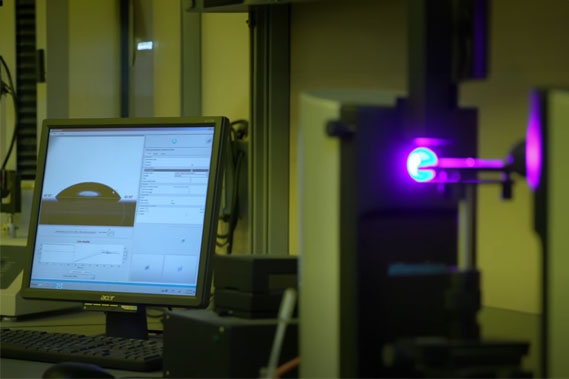

El equipo de prueba de dinas se utiliza para medir el ángulo de contacto de un adhesivo.

y calcular su energía superficial.

Cabe destacar que los sustratos específicos poseen inherentemente niveles de dinas compatibles con adhesivos de curado por luz UV, lo que elimina la necesidad de tratamientos de superficie. Algunos ejemplos de dichos sustratos incluyen ciertos tipos de vidrio limpio y algunos metales como el aluminio y el acero inoxidable. Estos materiales exhiben naturalmente una alta energía superficial, lo que los hace propicios para una humectación completa con adhesivos de curado por luz UV sin tratamientos adicionales. Sin embargo, es fundamental tener en cuenta que la limpieza de la superficie de estos sustratos puede afectar significativamente su nivel de dinas efectivo, y los contaminantes pueden reducir potencialmente la energía superficial por debajo de los requisitos del adhesivo.

El nivel de dinas es un parámetro esencial para los ingenieros de diseño, especialmente en aplicaciones de adhesivos UV. Influye no solo en la selección del adhesivo, sino también en los tratamientos necesarios del sustrato. Una comprensión completa y una medición precisa del nivel de dinas son cruciales para optimizar el proceso de adhesión, asegurando que los productos resultantes cumplan con los estrictos estándares de confiabilidad y durabilidad que exigen los mercados actuales.